-

Product DescriptionCompany Info.<>

- Species:

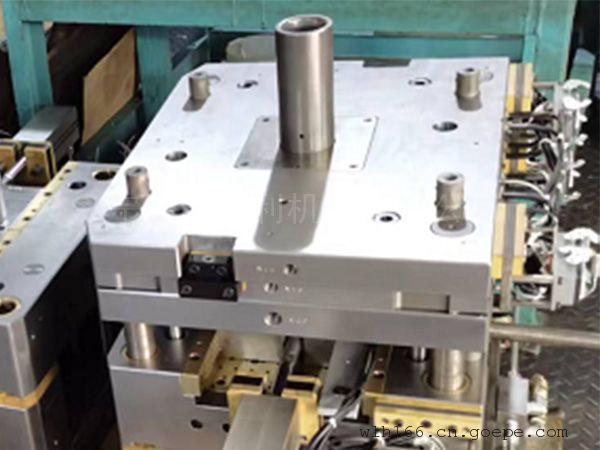

- Disc injection molding machine

- Model:

- XRT600-2R

- Product alias:

- Driving motor plastic sealing injection molding machine

- Product use:

- New energy vehicle drive motor iron core sealing

- Screw diameter:

- 36 mm

- Screw speed:

- 5-375 rpm

- Glue injection quantity:

- 130 g

- Ejector pressure:

- 1815 Mpa

- Theoretical injection capacity:

- 142 cm3

- Motor power:

- 7.5 kw

- Mold clamping force:

- 600 kN

- Mold opening stroke:

- 250 mm

- Weight:

- 3000 kg

- Overall dimension:

- 2800*1500*3400 mm

New energy vehicle drive motorcoreEME epoxy resin plastic injection molding machine

This injection molding machine is specially designed for new energy automobile drive motor core production line supporting the use of models divided into standard machine, skateboard machine, disc machine.

Brief Introduction of Skateboard Machine Technology

Molding mode:upper mold fixed,lower mold sliding back and forth

Flow:Put iron core-slide in-mold closing-handle feeding-pressure injection-pressure holding curing- mold opening-slide out-core removal-recycling

Disc injection molding machine process brief introduction

Molding mode: upper mold fixed, two pairs of lowermold alternately into molding

Process: Astation put iron core-turntable turn-mold closing-handle feeding-pressure injection-pressure holding curing-mold opening-turntable turn-take iron core-recycling. Remark: Station Bcan providestacking,core taking and putting operations between station A and station B. Thetime is about90 seconds (thetime required for curing of station A).

Brief Introduction of Standard Machine Process

Molding method:upperandlower simple heating tools fixed on the upper and lower templates, small molds and productsas a whole loading and unloading

Process:stack iron core and small mold outside the line-put the whole on the lower heating tool-mold closing-handle feeding-pressureinjection-pressure maintenance curing-mold opening— and iron core removal-re-circulation.

Core injection molding process description:

The injection molding machine opens the mold and waits for the manipulator 1 to transplant the combined iron core and small mold from the heating station to the injection molding machine and heat assembly.(The heating tool and the mold plane are positioned in the way of positioning pins) After the injection molding machine receives the signal of the completion of the placement of the robot 1, the injection molding machine gives the robot 2 a signal to request the injection of the handle. The robot 2 grabs the preheated handle from the preheating machine to the injection molding machine and puts it into the injection molding machine.(Note: Robot 2 needs to calculate the time to take out the handle material from the discharge bin and put it into the preheating machine in advance) Injection molding machine clamping press presses the handle material into the mold at a certain speed, pressure and material amount, and maintains the pressure during solidification. Injection molding machine mold opening robot 1 removes the product and small mold as a whole and puts it into a new product recycling 3. Upper tooling cleaning: Sticking may occur at the joint of upper heating tool and small mold, so it is necessary to clean the surface of upper heating tool every mold or several molds. The cleaning method can be applied with special medicine (recommended by raw material manufacturer) or brush cleaning and dust absorption.—— ———— —— ——— — ———— ——

- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together!- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together! -

Send your message to this supplier*From:*To:

Mr. Lihui Wei

*Message:

Mr. Lihui Wei

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.