-

Product DescriptionCompany Info.<>

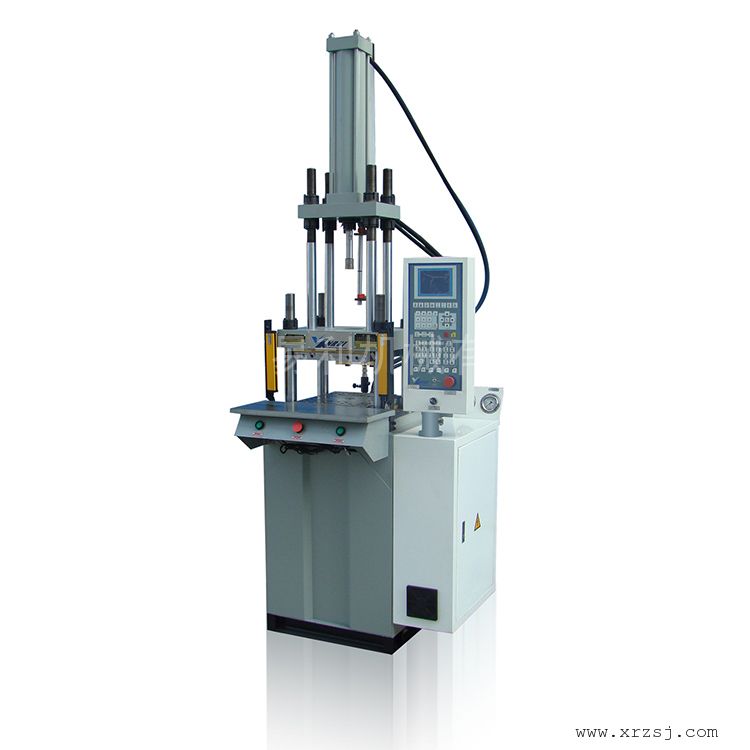

- Species:

- Disc injection molding machine

- Model:

- XRT400-ZDZS-2R

- Product alias:

- BMC Vertical Disc Injection Molding Machine

- Product use:

- BMC products injection molding

- Screw diameter:

- 40 mm

- Screw speed:

- 5~240 rpm

- Glue injection quantity:

- 403 g

- Ejector pressure:

- 1203 Mpa

- Theoretical injection capacity:

- 252 cm3

- Motor power:

- 5.5 kw

- Mold clamping force:

- 400 kN

- Mold opening stroke:

- 200 mm

- Weight:

- 2.5 kg

- Overall dimension:

- 2400*1400*3100 mm

XRT series injection molding machine features

1 vertical injection, vertical clamping structure design, small footprint, conducive to saving workshop space.

2 Diversified clamping mechanism design, with different characteristics and requirements of large and small models, to achieve economic, simple, stable, fast and precise requirements.

----Letter cylinder design: fast speed, high efficiency,(25~60 tons below the model).

----Double fast cylinder design: fast speed, high efficiency,(60~800 tons model).

3. The movable parts of the template and the machine column match the characteristics and requirements of different sizes to achieve smooth movement, no pollution, long service life and high precision.

----Self-lubricating bearings: wear-free (25~100) tons models.

----High rigidity copper bushing; self-lubricating bearing, no wear (120~800 tons).

4 Injection molding system adopts double injection cylinder, double seat cylinder, double guide column design (except for 25 tons), stable movement, high injection precision.

5. Imported motor (25~80) tons and five-star motor (90~800) tons are used for feeding, high torque and low noise.

6 Single slide plate, double slide plate and turntable models of mold installation, disassembly is convenient, high security, can greatly improve production and efficiency.

XRT series injection molding machine standard configuration

1 Safety grating device

2 Screw cold material protection device.

3 Emergency stop safety switch.

4 P.L.D proportional temperature control.

5 Automatic fault display and shutdown.

6 full computer screen display electronic control.

7 double button switch safety

XRT series injection molding machine selection device

1 Spring nozzle device.

2 Automatic alarm device.

3 drying door or automatic suction machine.

4 Neutron devices.

5 zipper blowing device.

6 Mechanical protection devices.

7 Automated embedded systems.

8 Thermosetting injection molding system.

9 Dual-color, multi-color injection system.

10 oil circuit full (half) closed loop device.

11 Accumulator device.

12 Special electrical and hydraulic unit devices.

Thank you for your continued attention to our products, if necessary, we will be happy to serve you! Mobile: Wei Lihui

1. Mechanical oil circuit part of new injection molding machine:

1, high efficiency: double oil supply system can be selected, the machine in the mold clamping thimble action can be carried out at the same time with the mold clamping. A cycle can save 2-3 seconds, greatly improving production efficiency.

The turntable is equipped with a high-speed motor to drive a specially designed gear turntable, and the time from initial to positioning is only 1.5-2 seconds.

2. High safety: the drive of the turntable is smooth and smooth, and the insert is not easy to slide; and it has 3 re-positioning, which can work at high speed, mute and without impact, keep the speed consistent with the set value, and can automatically correct the difference linearly. In addition to conventional low-voltage safety mold locking, abnormal automatic mold opening, automatic fault display and other functions, another optional infrared safety grating. The rotation speed of the turntable changes slowly from the initial to the positioning, the rotation is very fast and smooth, the positioning is gentle and accurate, and the safety of personnel and molds is protected to a great extent.

Because the sliding plate machine is driven by oil cylinder, the sliding speed of the sliding plate is also different when the oil temperature is different, and it is easy to form impact deformation on the positioning of the cylinder body. Inaccurate positioning from the formation causes mold damage, and because there is a collin column obstacle in the middle of the workbench sliding left and right, employees are easy to clamp the material handle from the unprotected middle gap, forming a major safety hazard.

3, manufacturing precision: the rotation of the turntable by high-precision gear drive, smooth movement, inserts are not easy to slide; and with triple positioning: from the oil circuit, circuit, mechanical aspects to give its precise positioning function, positioning accuracy up to 0.01mm. High-tech control operating system support high-precision positioning, according to the slow fast slow working state rotation, whether rotation or positioning can be kept fast, gentle and accurate.

4, stable operation: general manufacturers machine with hydraulic oil temperature difference, oil motor speed will change will lead to positioning error. The new sharp series rotary table machine is designed with ultra-high response electro-hydraulic proportional flow valve (with position control) on the oil circuit. Advantages are as follows:

a. The flow value can be changed along a slope line in a short time, so that the disk can smoothly transition to slow speed;

b. Increase the speed of the disc during idle travel to save time;

c. Reduce the impact force of mechanical limit, prolong the service life of mechanical limit, and reduce noise;

d. Significantly improved controllability;

And powerful high-tech control operating system supports high-precision positioning, according to slow fast slow working state rotation, whether rotation or positioning can be maintained quickly, gently and accurately.

5, saving space and labor: turntable machine occupies a small space, according to XRT-250R turntable machine to calculate, turntable width is only 1.2 meters, 25 tons of skateboard machine due to the structure of the pull rod and skateboard, its 2.4 meters wide enough to swing two turntable machine. The turntable only needs one operator to take out the products and place the inserts at the ejection station, and the operation is relatively standardized and simple; when the skateboard machine is operated, the operation space is narrow due to two collins blocking the middle mold closing position, and there are safety loopholes. If the standard operation requires two people to work at the same time, there must be a tacit cooperation. It saves half the manpower and space compared to a skateboard.

6, higher speed: special design of the turntable at the same time, XRT-250R machine or above series more scientific design to achieve a lighter rotation, more quiet, more accurate and expanded more mold space!

Second, the cutting-edge injection molding machine controller part:

1: The computer adopts high-tech control system computer, CPU uses 16/32 bits, and the response is fast. Dual CPU control, 68 sets of mold parameters memory.

2: Five-stage PID closed-loop temperature control, ten-stage linear correction for the difference, temperature control up to 0.5℃.

3: With temperature following curve page display, it is helpful to analyze and improve product quality.

4: Four-stage mold opening and closing pressure flow setting, and four-stage injection, three-stage pressure maintenance. Feeding two stages and after the release, injection before feeding settings. High precision product requirements can be guaranteed. All movements of the machine switch smoothly without shock and vibration.

5: PQ control, namely proportional pressure flow control. With ten linear correction function, can be different brands of proportional valve nonlinear correction. This ensures stable operation of the machine.

6: With screw speed measurement function, can dynamically monitor the feeding status.

7: Non-contact solid-state relay control heating function, the service life is twice as long as that of contact relay.

8: With position ruler broken line observation, instant judgment sensor fault.

9: Thermocouple disconnection intelligent detection function.

10: With production management function, it has three functions of injection end point, cycle time and shutdown condition for production control. With injection tracking curve, and automatic statistics of qualified products and waste, instant grasp of product quality variation, can be equipped with automatic production computer control system management.

Basic functions are not listed. The above points are for reference.- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together!- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together! -

Send your message to this supplier*From:*To:

Mr. Lihui Wei

*Message:

Mr. Lihui Wei

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.