-

Product DescriptionCompany Info.<>

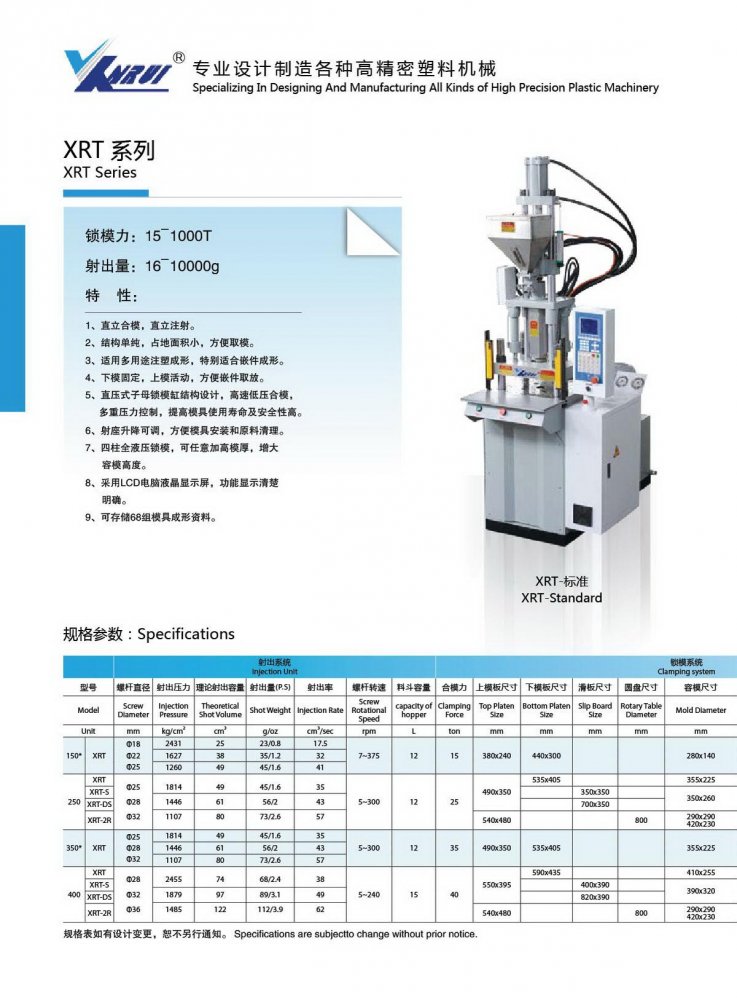

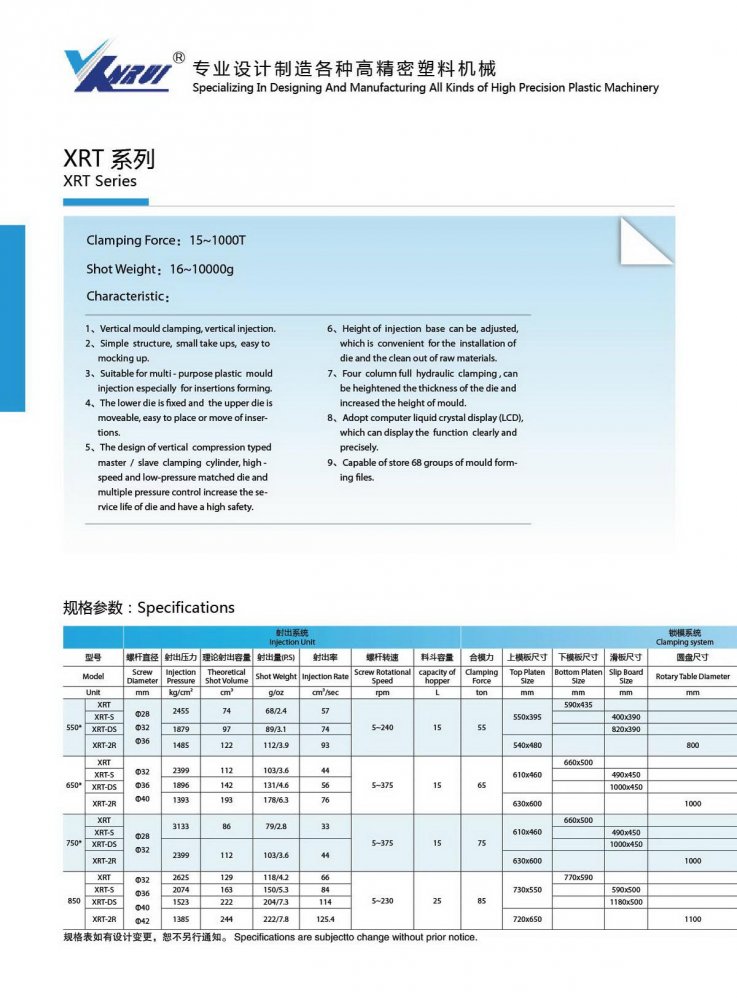

- Species:

- Multi-loop injection molding machine

- Model:

- XRT-400

- Product alias:

- Vertical Injection Molding Machine

- Product use:

- Injection molding of thermoplastic products

- Screw diameter:

- 28 mm

- Screw speed:

- 5~300 rpm

- Glue injection quantity:

- 68 g

- Ejector pressure:

- 2457 Mpa

- Theoretical injection capacity:

- 74 cm3

- Motor power:

- 5.5 kw

- Mold clamping force:

- 400 kN

- Mold opening stroke:

- 200 mm

- Weight:

- 1300 kg

- Overall dimension:

- 1.8*1.1*2.9 mm

XRT-400 high-precision vertical injection molding machine features:

1, humanized workbench height design, suitable for large models, comfortable operation, thereby reducing the operator's labor intensity, improve work efficiency and ensure safety.

2. The clamping mechanism adopts fast cylinder design to achieve stable, fast and easy maintenance requirements.

3. The movable parts of the template and the machine column adopt high rigidity copper bushings to achieve smooth movement, no pollution and long service life.

4. Injection molding system adopts double injection cylinder and double guide column design, stable movement and high injection precision.

5, feeding using five-star motor, can meet the different requirements of high torque or high speed.

6, complete models, with standard machine, double slide machine, turntable machine (2 stations, 3 stations and multi-station) to choose from, to meet the diversified needs of injection molding.

7, double-lock mold installation, disassembly is convenient, high security, can greatly improve production and efficiency.

8, mold adjustment separate side control, convenient and safe from the perspective, user-friendly angle to facilitate rapid replacement of molds.

9. Humanized design of shooting platform lifting system, convenient, safe, fast, time-saving and labor-saving mold adjustment or mold change.XRT-400 high-precision vertical injection molding machine electric control function characteristics

1. The computer adopts international high-tech original computer control system, CPU uses 16/32 bits, and the response is fast. Dual CPU control, 68 sets of mold parameters memory.

2, five-stage PID closed-loop temperature control, the difference for ten linear correction, temperature control up to 0.5℃. Temperature control can also be fuzzy

Control function, accurate temperature control, high stability, easy to operate.

3, with temperature tracking curve page display, help to analyze and improve product quality.

4, four-stage mold pressure flow setting, and four-stage injection, three-stage pressure. Feeding two stages and after the release, injection before feeding settings. High precision product requirements can be guaranteed. All movements of the machine switch smoothly without shock and vibration.

PQ control, namely proportional pressure flow control. With ten linear correction function, can be different brands of proportional valve nonlinear correction. may

Ensure that the machine runs stably.

6, with screw speed function, can dynamically monitor the feeding situation.

7, the use of non-contact solid-state relay control heating function, the service life is twice as long as the contact relay.

8, with a position ruler broken detection, instant judgment sensor failure.

9. Thermocouple disconnection intelligent detection function.

10, with production management functions, with injection end point, cycle time, shutdown conditions three functions for production control.

11, injection tracking curve, and automatic statistics of qualified products and waste, even if the grasp of product quality variation.

12, can be equipped with automated production computer control system management.

13. A variety of ejection functions (fixed time, stay) to meet the requirements of different injection molding processes.

14. Feeding adopts multi-stage pressure and speed control, and has front and rear loose control, accurate and stable measurement.

15, automatic seat back function, can be different according to the fluidity of plastic, set to the end of measurement and cooling action.

16, automatic cleaning function.

17. Temperature upper limit and lower limit temperature difference setting to ensure that the deviation value of actual temperature is within the set range.

18. The temperature of each section can be controlled on and off independently.

19, cold start prevention function, can avoid screw damage in the early stage of cold rotation.

20. Temperature preheating function saves heating time.

21. Password setting and data protection function.

22, random storage of 68 sets of mold molding parameters.

23, module memory can be Chinese and English input mold name.

24, input/output status monitoring, status monitoring is conducive to maintenance inspection.

25, action program humanized design, operation error, alarm prompt.

26, each parameter setting has help tips, operation errors have alarm tips.

27. Operation panel key fault detection page.28. Each action has switch delay, pressure and speed slope control, and the whole machine runs smoothly without impact.

Please click on the sample image for detailsPlease click on the sample image for detailsPlease click on the sample image for detailsPlease click on the sample image for detailsPlease click on the sample image for detailsPlease click on the sample image for details- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together!- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together! -

Send your message to this supplier*From:*To:

Mr. Lihui Wei

*Message:

Mr. Lihui Wei

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.