-

Product DescriptionCompany Info.<>

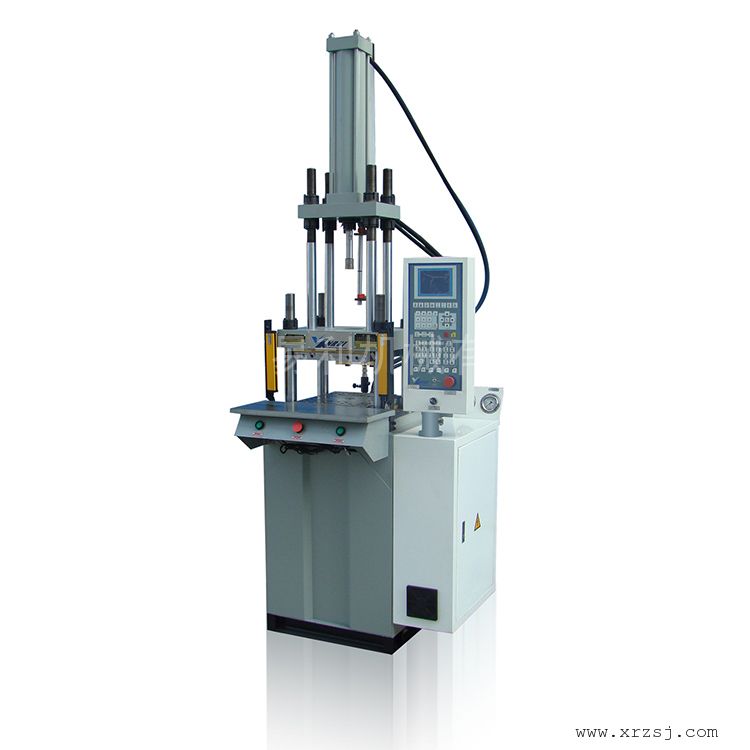

- Species:

- Disc injection molding machine

- Model:

- XRT400-ZDZS-2R

- Product alias:

- injection molding machine

- Product use:

- Plastic products and other special vertical injection molding machine injection molding

- Screw diameter:

- 36 mm

- Screw speed:

- 5~240 rpm

- Glue injection quantity:

- 112 g

- Ejector pressure:

- 1486 Mpa

- Theoretical injection capacity:

- 122 cm3

- Motor power:

- 7.5 kw

- Mold clamping force:

- 400 kN

- Mold opening stroke:

- 200 mm

- Weight:

- 2300 kg

- Overall dimension:

- 2400*1200*3000 mm

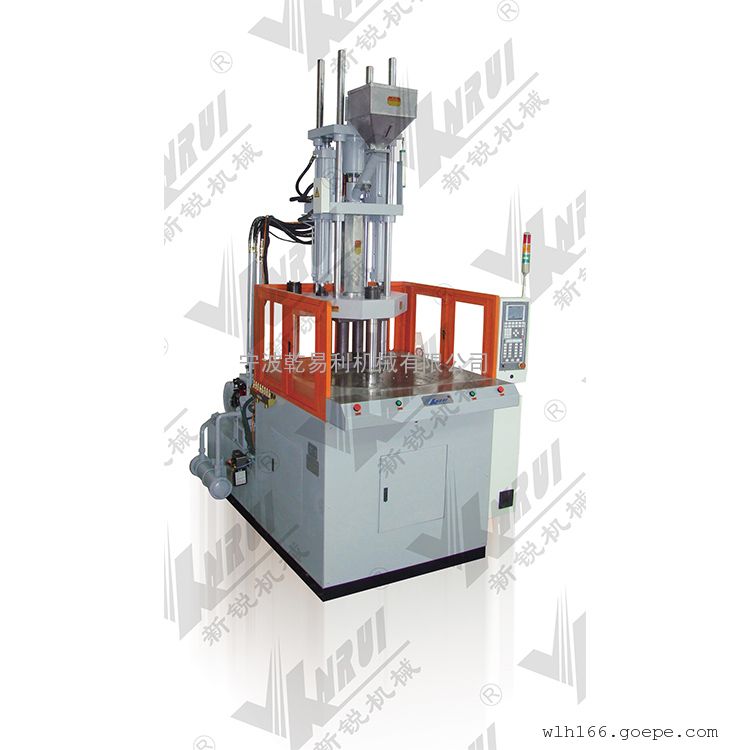

XRT series injection molding machine characteristics

1 vertical injection, vertical clamping structure design, small footprint, conducive to saving workshop space.

2 Diversified clamping mechanism design, with different characteristics and requirements of large and small models, to achieve economic, simple, stable, fast and precise requirements. ----Letter cylinder design: fast speed, high efficiency,(25~60 tons below the model). ----Double fast cylinder design: fast speed, high efficiency,(60~800 tons model).

3. The movable parts of the template and the machine column match the characteristics and requirements of different sizes to achieve smooth movement, no pollution, long service life and high precision. ----Self-lubricating bearing: no wear (25~100) tons. ----High rigidity copper bushing; self-lubricating bearing, no wear (120~800 tons).

4 Injection molding system adopts double injection cylinder, double seat cylinder, double guide column design (except for 25 tons), stable movement, high injection precision.

5. Imported motor (25~80) tons and five-star motor (90~800) tons are used for feeding, high torque and low noise.

6 Single slide plate, double slide plate and turntable models of mold installation, disassembly is convenient, high security, can greatly improve production and efficiency.

Comparison between XR series rotary table machine and standard machine 1. High efficiency: The efficiency of the Star Rui series rotary table machine is 50%~80% higher than that of the standard machine. The working mode of the rotary table machine is that one upper mold and two bottom molds perform interactive rotation operations (or three The bottom mold works clockwise for higher efficiency). When one mold is rotated in place for mold clamping and injection molding, the other mold is moved to the front of the operation to remove the product and place the inserts. Standard machine from mold to mold opening this period of time, the operator can not place complex inserts to form a waste of time, not effective use of mechanical dynamic resources; disk machine is just in this same time period with the standard machine put more than one mold insert, that is, more than one mold of the product. For those products that require a lot of inserts or very complex inserts, the turntable machine not only brings you a double increase in output, but its precision injection system will also give a good improvement in product quality. 2, high safety: the operator takes out the product when the upper limb of the working range outside the mold area. In addition to conventional low-voltage safety mold locking, abnormal automatic mold opening, automatic fault display and other functions, can also be equipped with infrared safety grating. The rotation speed of the turntable changes slowly from initial to positioning, the rotation is very fast and smooth, and the positioning is also very gentle and accurate, which protects the safety of personnel and molds to the greatest extent and greatly prolongs the service life of the machine. 3, energy-saving: for some products molding required cooling time is very long, this series of plastic machine special design of the motor intelligent energy-saving program will give you a lot of savings in electricity; the equipment efficiency, but the floor space and energy consumption than the standard machine has not increased. 4, humanized design: can freely adjust the height of the thimble, simple and easy to learn and easy to operate the vertical touch screen, low workbench and many other details all bringgreatconvenience and efficiency to your production. The standard machine thimble can only be adjusted according to time and pressure, and the expected effect cannot be achieved. 5. Stable operation: the rotation of the turntable is driven by high-precision gears, the movement is smooth and smooth, and the inserts are not easy to slide. It is equipped with oil temperature compensation valve, which can ensure that the rotation speed of the turntable can maintain high speed and quiet rotation according to the set value no matter in the case of hot oil or cold oil; and the powerful high-tech control system supports high-precision positioning, according to the slow-fast-slow working state rotation, whether it is rotation or positioning can maintain rapid, gentle and accurate. 6. Reduce the labor intensity of operators.- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together!- Name(chinese)

- Name(English)

- Ningbo Qianyili Machinery Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Yuyao City, Ningbo, Zhejiang, China

- Nearby port

- Shanghai,Ningbo

Ningbo Qianyili Machinery Co., Ltd.(formerly Jiangsu Qianyili Intelligent Technology Co., Ltd.) is a plastic machine and automation enterprise that has accumulated many years of professional management, research and development, independent scientific and technological innovation, manufacturing, sales, and service integration. The company specializes in the production of vertical, angular thermoplastics, thermosetting [PF UF MF BMC DMC SMC DAP,,,,], liquid silicone rubber, powder metallurgy, hard magnetic injection, metal powder injection, ceramic injection, special engineering materials and other machinery; Provide customers with safe, fast, efficient, environmentally friendly, energy-saving; two-color and multi-color, full [half] closed-loop, accumulator [fast glue injection], servo control, oil-electric hybrid, all-electric, various special machines and automation equipment. The R & D department of Ningbo Qianyili Machinery Co., Ltd. has long-term collaboration with top research institutions in machinery, hydraulics, and electricity at home and abroad to create faster, newer, better, more energy-saving, environmentally friendly, automated, and user-friendly equipment with the development of the market. We adhere to the concept of putting people first and innovative technology, win the trust of the market with quality, seek development with integrity, and provide a full range of professional technical support and planning. Innovate and develop together with customers, operate continuously, and move towards a better tomorrow together! -

Send your message to this supplier*From:*To:

Mr. Lihui Wei

*Message:

Mr. Lihui Wei

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.